A customer recently needed a system to move variously sized cartons through two inkjet printers. During this process, the carton… Read more »

Tag: Belt Conveyors

Vertical Precision Move Conveyor for Elevation Changes in Manufacturing Line

Manufacturing lines aren’t always on a single level. For this paper company, the product accumulator was 20 feet above the… Read more »

Reducing Product Loss

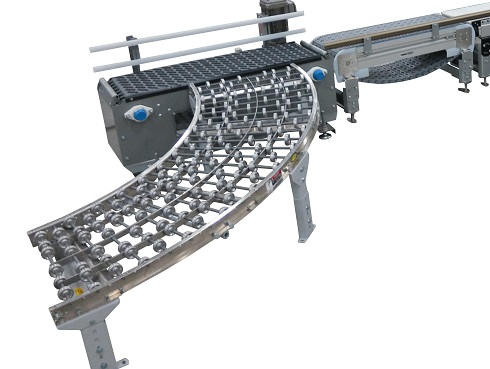

When you need to move product from one conveyor to another that’s often where challenges arise. You could just put… Read more »

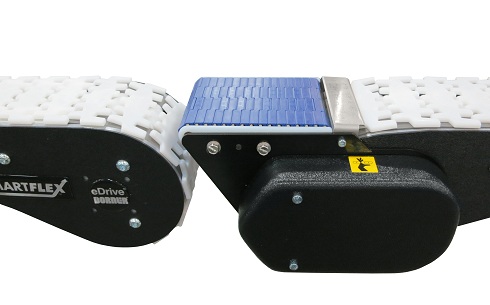

Belt or Chain, Belt vs. Chain – Not Really

What makes a belt better than a chain and vice versa? The answer is nothing. Belts are no better than… Read more »

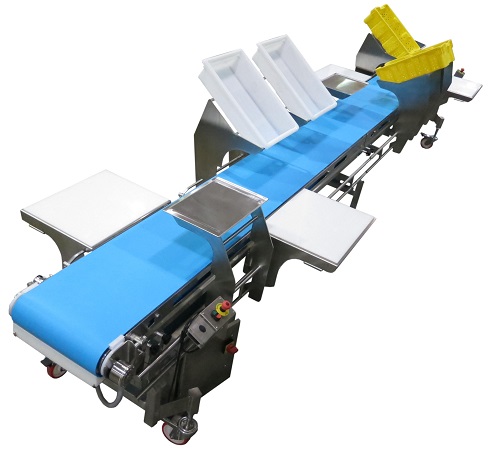

Improving a Ready-to-Eat Assembly

Recently, one of our customers requested a versatile assembly conveyor for its popular ready-to-eat sandwich products. To meet their needs,… Read more »

Beverage Packaging Solution Takes Wine Bottles for a Spin

On a past project, a customer had problems consistently sealing the bottles of wine they produced. The challenge was to… Read more »